Modi govt’s steel silos plan can stop loss of stored foodgrains

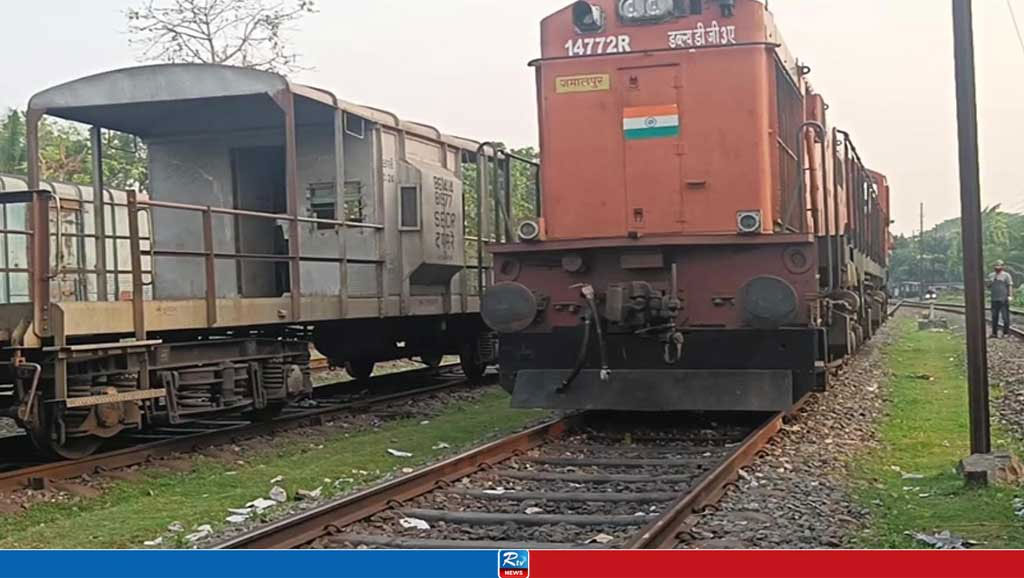

The central government of India will soon set up modern food grain storage across the country in the form of steel silos. This is expected to make the storage process more resistant to grain loss, and thus, cost-effective. The Food Corporation of India handbook on food storage operations management estimates that the use of scientific storage practices, if followed, can reduce total loss by about six per cent, thereby saving Rs 1,350 crore every year. Most importantly, this will make available an additional nine million tonnes of foodgrain for public consumption.

These steel silos, with a total capacity of almost 11 million tonnes, will be established in 249 sites. It is estimated that the storage structures will bring down grain leakage and losses incurred by conventional baggage storage methods.

The plan is to adopt a ‘hub and spoke’ model, where several silos will be connected to a larger one with rail connectivity. “We have prepared an action plan to implement the evacuation of the entire stock in Cover and Plinth (CAP) type of open food storage by March 2022 to scientific storages,” said FCI chairman and managing director Atish Chandra. FCI is the nodal central agency tasked with foodgrain procurement and distribution across the country “Steel silos, with a capacity of 2.875 LMT (lakh metric tonnes) at six locations have also been completed in 2021 and silos with 3.125 LMT at six locations are likely to be completed in the next six months,” Chandra detailed. “Hub and spoke silos with a capacity of 108.375 LMT at 249 locations are also planned to be constructed in a phased manner. Construction of silos at 80 locations with 32.5 LMT capacity will be taken up in phase one, for which the appraisal process is underway,” he added.

Avoiding severe food grain losses

According to the FCI handbook, scientific storage is pest- and damp-proof, and allows sufficient ventilation with openings for carrying bags of grain. It also enables maximum utilisation of the floor areas by providing the necessary loading and unloading platforms. On the contrary, bagged wheat is often stored in CAP storages, in the open, during peak procurement season, due to the huge inflow of wheat in mandis. However, these storages are susceptible to multiple weather- and pest-related vagaries, leading to severe foodgrain losses.

In the handbook it is also mensioned that while India produces about 150 million tonnes of foodgrain a year, losses have remained static at 10 per cent of that amount, or 15 million tonnes. The main culprit is improper storage — responsible for the loss of an average about nine million tonnes, or 60 per cent of the total loss.

Pilot project for steel silos

The central government also undertook a pilot project to assess the viability of foodgrain storage in steel silos. “The pilot project on rice silo is still being executed at Kaimur and Buxar in Bihar,” Niraj Kumar Singh, chief of the silo project in the National Commodities Management Services Limited (NCML), told ThePrint.

“The target was to store 12,500 MT of milled rice at each site in four silos of 3,125 MT each. Both sites will have three steel tower silos with 12,500 tonnes capacity each for storing wheat and four steel silos with 3,125 tonnes capacity each for storing rice. At both these places, FCI will import wheat from other regions for distribution there, while rice will be procured locally and stored before being used in whichever way the corporation deems fit,” Singh explained.

Explaining the hub and spoke system of construction of new silo terminals, he said: “Only the ‘hub’ terminal will have rail siding. Its ‘spoke’ terminal won’t have any rail siding, as the latter depends on the hub for all its rail movements. One hub terminal can service multiple spokes.” “From the date of land acquisition, it takes only 12 months to construct a silo storage terminal of 50,000 MT, except a rail siding, which may take another month,” he added.

According to his estimates, compared to a conventional godown, storage in modern steel silos reduces grain storage losses to a large extent, by eliminating rodent and vermin infestation, spillage, bird droppings and pilferage. Being a closed system, silo storage keeps grain storage losses at less than 0.5 per cent — a massive advantage.

Mechanisation and monitoring systems

Singh also noted that conventionally in India, grain is stored in jute or polybags of 50 kg each in godowns, and handling them requires a lot of manual labour, making it inefficient and slow. However, silos can be easily mechanised and have a high grain handling speed of up to 700 tonnes an hour.

Foodgrains stored in silos also have grain condition and moisture monitoring systems. Temperature can be regulated too. Some of the most advanced silos even have a carbon dioxide monitoring system — used for very early pest and insect infestation warnings — besides being equipped with a highly effective closed-loop fumigation system.

Source: The Print

Comments

Japan's yen dips to 34-year low against US dollar

Decoding China’s Neo-Colonist practices in Africa

Jacob Zuma barred from running in election

45 dead in South Africa bus crash, 8-year-old girl only survivor

World's most expensive cow sold for $4.3 million in Brazil

Turkey: Polls close in Erdogan's 'last election'

Italy is overtaking Germany as Europe's economic powerhouse

Live Tv

Live Tv